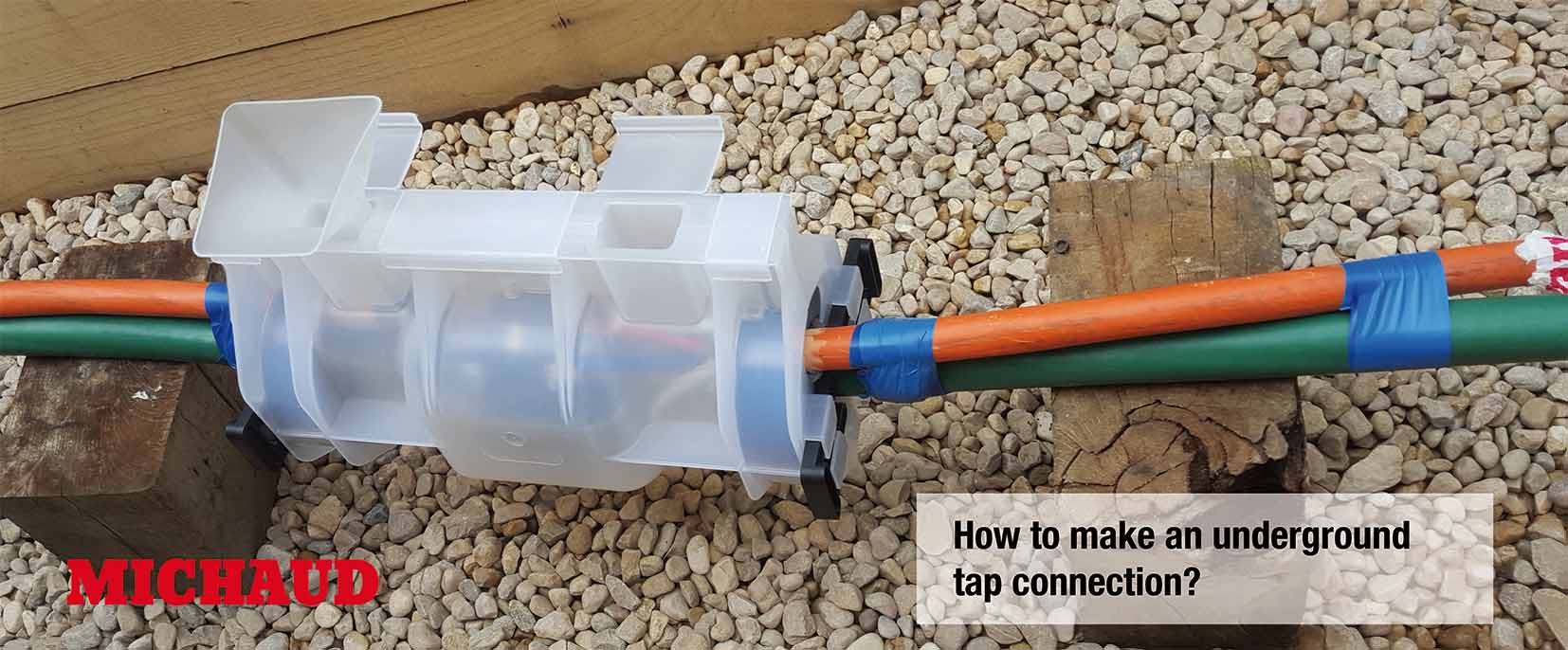

Underground networks are essential for electricity distribution and for supplying end users. From a main distribution cable, underground electrical tap connections can be created to connect customers or supply a specific area, such as a street or a residential development.

To achieve this, the most commonly used solution is an underground junction box, made up of three main components: the connector, the resin, and the enclosure (or shell). Before selecting these components based on their technical characteristics, it is necessary to define the type of tap to be carried out: is it a service connection (customer connections) or a network tap? The cable cross-sections involved and the electrical current transmitted directly influence the choice of the system, particularly the type and size of the connector.

Different connectors for an underground tap connection

In underground environments, two main types of connectors are used: single-pole and multipole connectors.

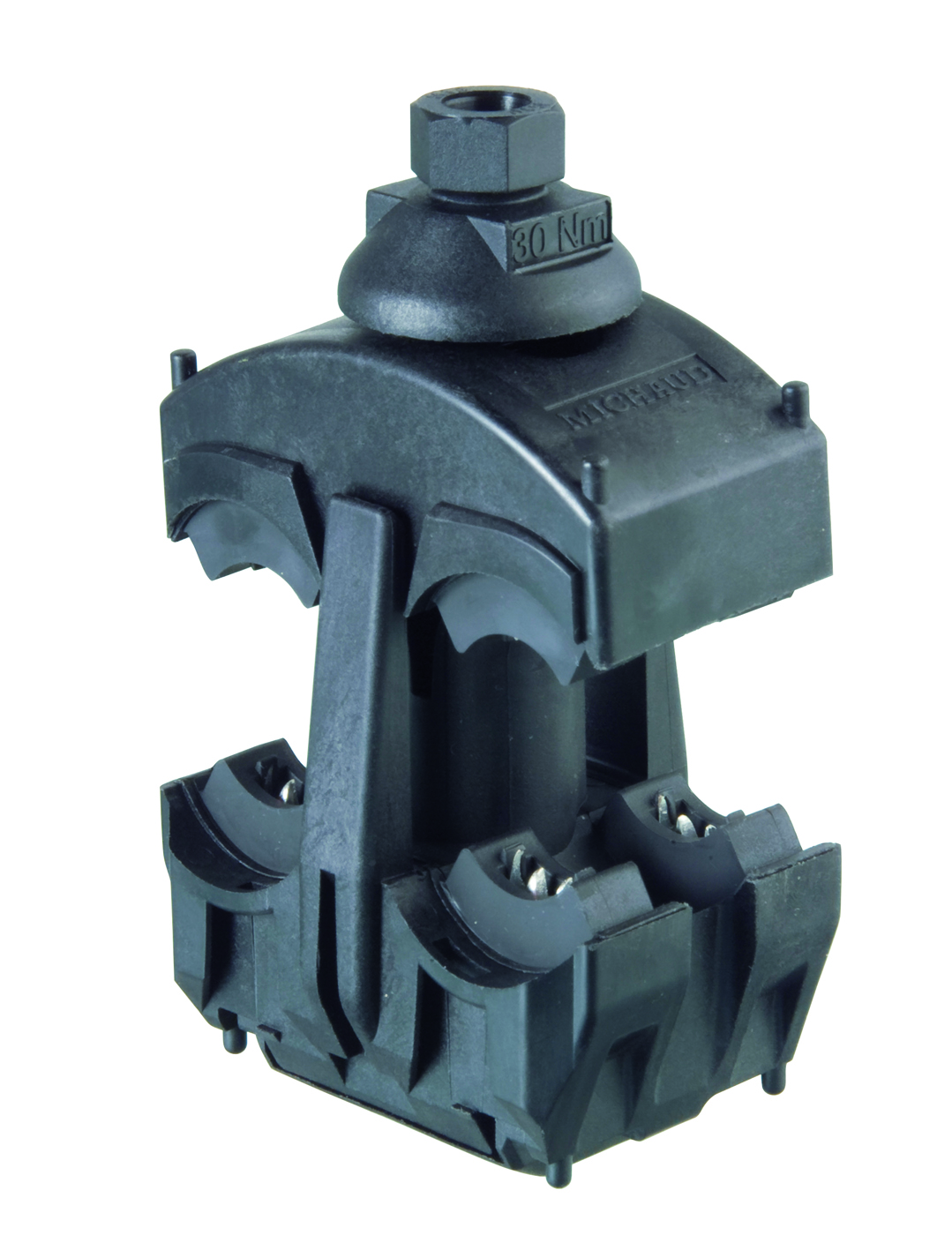

Single-pole connectors

Each conductor (phase and neutral) is tapped individually. A connector is therefore required for each conductor, meaning four connectors for a single-phase line. This solution, which is also used in overhead networks, offers a certain degree of flexibility but requires more handling during installation.

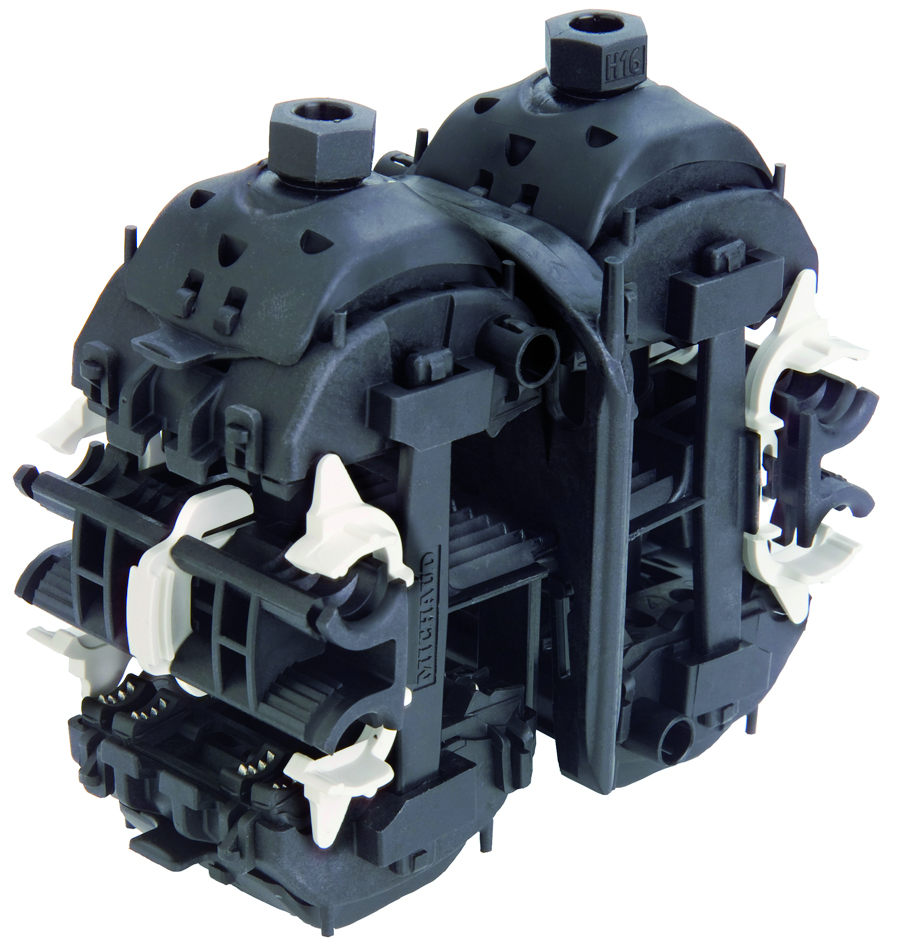

Multipole connectors

This type of connector surrounds all the conductors of the main cable in a single unit. It is generally fitted with only two screws, making installation easier. With a single tightening operation, the connector establishes the connection between the main cable and the tap cable. This system ensures balanced distribution of mechanical stress and saves space, while reducing installation time.

The importance of resin for watertightness

Underground, watertightness is a critical concern. To ensure long-lasting protection against moisture, an encapsulating resin is used, capable of filling all gaps around the connection and creating a watertight block once cured. This resin is generally supplied in a bucket, container, or dual-chamber pouch and hardens when mixed with a hardener.

There are several types of resin, each with different properties:

- Soft or hard once cured

- Removable or non-removable

- More or less environmentally friendly

The choice depends on local technical constraints, applicable standards, and the desired performance, such as impact resistance, storage life, thermal conductivity, and so on.

How to secure the elements of the tap connection?

To allow the resin to form a protective casing around the underground connection, a containment element called an enclosure or shell is added. Two main options are available:

The rigid shell

It provides additional mechanical protection, particularly against impacts and ground movement. It requires the use of pourable resin, which is directly poured inside.

Flexible wrapping (tape type)

Less bulky and more cost-effective, it requires injected resin. This method allows for a reduced amount of resin, as the area to be filled is smaller. It is more technical but advantageous when space is limited or budget constraints apply.

The amount of resin required will therefore depend on the chosen technology, the size of the connectors, and the number of tap connections to be made.

Carrying out an underground electrical tap connection according to best practices

First and foremost, it is essential to prepare the worksite. A trench must be dug wide and deep enough to ensure safe and proper working conditions. This may involve removing surface coverings (asphalt, paving stones, etc.) and using construction machinery, which helps explain the higher cost of these installations.

Once the excavation is completed, technicians can proceed with:

1. Preparing the conductors

2. Installing the connectors

3. Placing the enclosure

4. Pouring or injecting the resin

5. Allowing it to cure according to the manufacturer’s instructions

Before backfilling the trench, the installation must be inspected. A warning mesh (often red or orange) is then placed a few centimeters above the system to signal the presence of an electrical network during future work. This visual warning is sometimes complemented by additional mechanical protection.

Finally, these works must be carried out by teams trained in underground installation techniques to ensure safety, compliance, and long-term reliability of the installation.